2025-06-16

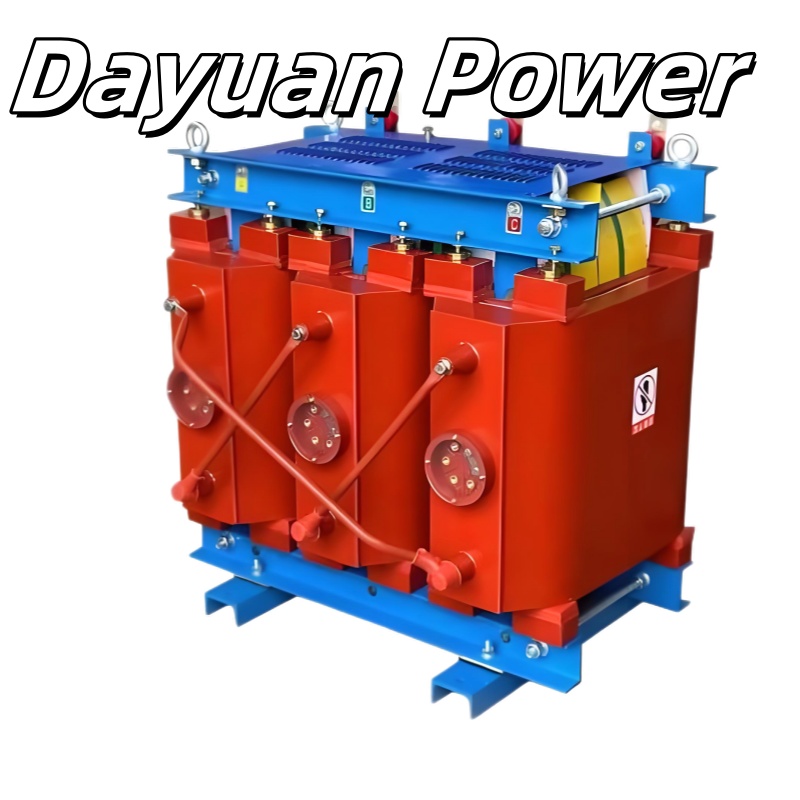

Dry-type transformers are manufactured by using air and solid insulating materials. Our company produces various types of transformers. They possess safety, environmental friendliness, and flexibility for indoor installation. They are the preferred choice for most commercial, institutional, and many industrial applications, as these places do not allow the presence of fire risks or environmental pollution caused by liquid leakage.

1.No Liquid Coolant/Insulant: This is the defining feature. Heat generated during operation is dissipated directly into the surrounding air.

2.Insulation Materials: Windings are insulated using high-temperature, flame-retardant materials:

Vacuum Pressure Impregnated (VPI): Windings are dipped in resin under vacuum and pressure, creating a tough, sealed insulation barrier.

Vacuum Pressure Encapsulated (VPE): Similar to VPI but often uses multiple dips for a thicker coating.

Cast Resin (Cast Coil): Windings are completely encapsulated (potted) in solid epoxy resin within a mold. This provides superior protection against harsh environments.

3.Cooling Methods:

Natural Convection (AN): Relies solely on the natural rise of hot air.

Forced Air (AF): Uses fans to blow air over the windings for enhanced cooling capacity (common for larger ratings or higher ambient temperatures).

4.Enclosure: Typically housed in ventilated enclosures (NEMA 1) to allow air flow. Enclosures can be upgraded (NEMA 3R for weather protection, NEMA 12 for dust/tightness) depending on the installation environment.

1.Enhanced Safety:

Non-Flammable: Eliminates the risk of oil fires, explosions, or leaks. Crucial for fire-sensitive locations.

Non-Toxic: No hazardous liquids mean no risk of soil or water contamination.

Lower Environmental Risk: No PCBs or other harmful fluids to manage or dispose of.

2.Reduced Maintenance: No need for regular oil sampling, testing, filtration, or leak monitoring associated with liquid-filled transformers.

3.Installation Flexibility:

Indoor Use: Can be installed directly inside buildings, close to the load (reducing costly feeder runs). Common in basements, electrical rooms, mezzanines, production floors.

Outdoor Use: Possible with appropriate weatherproof enclosures (NEMA 3R).

Vertical/Horizontal Mounting: Often more flexible than liquid-filled units.

4.Environmental Friendliness: No oil spills, no disposal issues for contaminated liquids, lower environmental impact overall.

5.Lower Noise Levels: Generally quieter than comparable liquid-filled transformers, especially cast resin types.

6.High Resistance to Contaminants: Cast resin and VPI/VPE transformers are highly resistant to moisture, dust, chemicals, and corrosive atmospheres.

1.Higher Initial Cost: Generally more expensive upfront than equivalent oil-filled transformers due to materials and manufacturing processes.

2.Limited Maximum Ratings: While constantly improving, the practical maximum voltage and power ratings for dry-types are generally lower than those achievable with large liquid-filled transformers (especially at transmission voltages).

3.Larger Physical Size: For the same power rating, dry-types are often physically larger than liquid-filled units (air is a less effective coolant than oil).

4.Lower Overload Capacity: Typically less tolerant of short-term overloads compared to liquid-filled transformers due to lower thermal mass and cooling efficiency.

5.Sensitive to Ambient Conditions: Performance can be more affected by high ambient temperatures, high altitude (thin air), or restricted ventilation. Adequate clearances and ventilation are critical.

6.Potential for Higher Losses: May have slightly higher core and copper losses compared to optimized oil-filled units, impacting efficiency (though modern designs are very efficient).

1.Commercial Buildings: Offices, shopping malls, hotels, hospitals, schools, universities, airports.

2.Industrial Facilities: Manufacturing plants, refineries, chemical plants (especially where fire/chemical resistance is critical), mines.

3.Marine & Offshore: Ships, oil platforms (with appropriate environmental protection).

4.Data Centers: Critical infrastructure requiring high reliability and safety indoors.

5.Renewable Energy: Wind turbines (nacelle installation), solar inverters.

6.Tunnels & Subways: Underground transportation systems.

7.Indoor Substations: Often located within buildings or dedicated electrical rooms.

1. Cast resin (cast coil): The highest level of protection, suitable for harsh environments, has the lowest fire risk, the least noise, and the most expensive price.

2. Vacuum pressure impregnation (VPI) / Vacuum pressure encapsulation (VPE): With strong protective performance, good moisture-proof/dust-proof ability, widely applied, suitable for various occasions, and high cost-effectiveness.

3. Open wound (ventilated type): Utilizes older technology, with only a very thin insulating coating (varnish/tape). This method has the lowest cost but is most susceptible to environmental damage; except for very small specifications, it has been largely replaced by VPI/VPE and cast resin.